MACHINE VISION

Manufacturers can speed production, minimize defects and reduce costs with machine vision technologies

What is Machine Vision?

Machine vision is a machine that has the ability to “see” to be used to check the quality of the production, because it is more accurate and accurate than it is used by people to check the workpiece errors. Able to work consistently and without fatigue like humans Which is a big cause of mistakes In addition, the system can inspect workpieces in every production process from the outset or in certain processes that humans are unable to inspect. Makes it possible to prevent damage early on

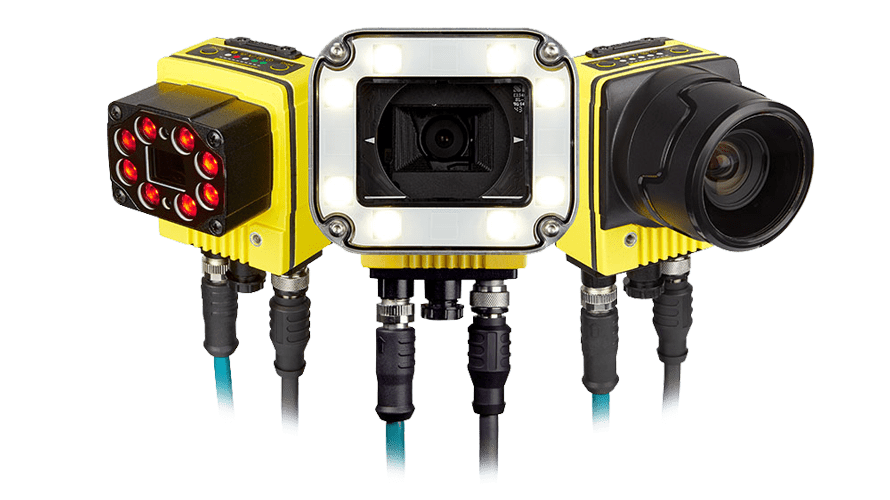

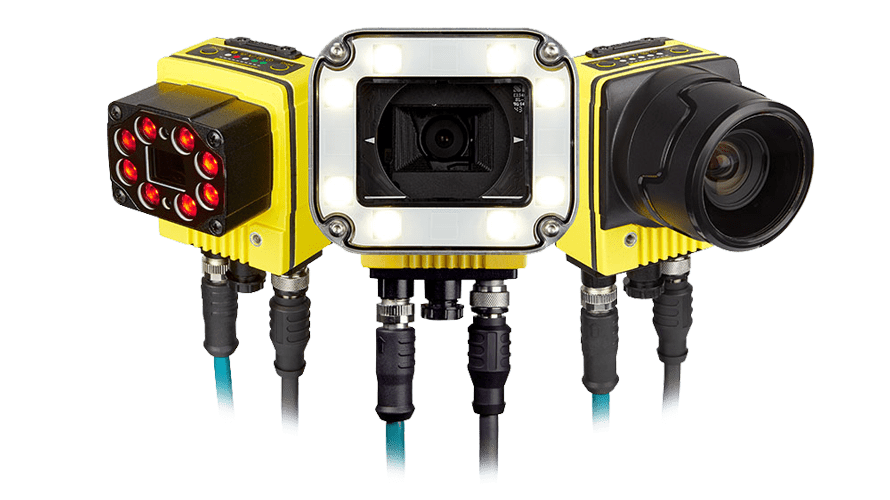

The Global Leader on Machine Vision and Industrial Barcode Reading

Cognex, the leader in vision systems and industrial decoders That has been most trusted With over one million systems installed in factories worldwide With over thirty-five years of experience, Cognex focuses on industrial vision systems and photo-based barcode readers from factories, manufacturers and operators to build world-class machinery for Cognex products. That the manufactured products will have the highest quality requirements in each industry

With nearly one million machine vision systems installed, Cognex is the world’s most trusted machine vision company. We have the people, experience, and knowledge to ensure the machine vision technologies you deploy do exactly the job you need to Make It Right for your customers.

Vision Systems Application

Inspection

Inspect assembly errors, surface defects, damaged parts and missing properties, identify and distinguish objects The shape and position of the object as well as the properties.

Guide/Align

Eyes of automation equipment and robots For component arrangement for high precision assembly Or other industries.

Gauge/Measure

Inspect parts to check important sizes Component measurement for sorting and classification.

OCR/OCV

Read and check Letters or numbers On the parts of the product directly And printed on the label.

Presence/Absence

Detects the presence or absence of certain objects or basic features on the product To send Pass or Fail results.

Code Reading

Read 1-D barcodes and 2-D matrix codes for applications that need to specify object-specific codes for inspections.